As a roofing supply pro, you sometimes find yourself invariably caught “in the middle” when delivering potentially problematic news — like price increases, color changes, product discos and do-not-mix scenarios — from the manufacturers to your contractors.

For several years, I had the good fortune of facilitating roofing contractor advisory council meetings across North America — from Buffalo, N.Y., to Boise, Idaho, Vancouver, British Columbia, to Toronto, and all parts in between.

Helping contractors deal with unexpected material price increases is critical to maintaining a good relationship.

One thing was always inevitable: contractors love the freedom to speak their minds and share ideas. Basically, these were organized “speak your mind” conversations; as I’ve mentioned before, contractors want to be heard and look to their suppliers for help succeeding in business.

Throughout these discussions, manufacturer price increases came up several times. A scenario I encountered, which is relevant to this discussion, is when manufacturers would issue a product price increase and, in some circumstances, a distributor would delay forwarding that information to the contractor.

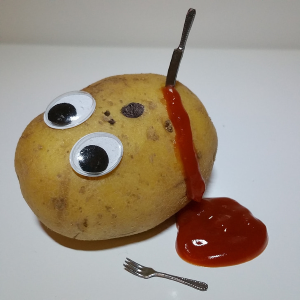

Unexpected Price Increases: A Hot Potato

Feeling blindsided by a lack of forewarning, contractors would say, “We lock in jobs several months down the road at ‘XYZ price,’ then get hit with a price increase when it’s too late to change the bid with the homeowner.” It’s not hard to see how this development puts everyone in a bind; in most cases, the contractor ends up eating the increase, or risks looking bad to their customer when he has to revise the bid after being awarded the job.

Sure, it’s a difficult conversation, and no roofing supplier shouts for joy when prices go up. Especially now, when we’re in tough inflationary times. The idea of passing on a price increase to contractors, who are already grappling with tight margins due to increased fuel and labor costs, not to mention the ancillary expenses of maintaining capital expenditures like vehicles, tools and other equipment, is challenging. An unanticipated materials increase puts a contractor already locked in pricing with clients into a difficult situation: Do they “resell” the cost hike to a customer or eat the difference in a loss leader strategy?

Sure, it’s a difficult conversation, and no roofing supplier shouts for joy when prices go up. Especially now, when we’re in tough inflationary times. The idea of passing on a price increase to contractors, who are already grappling with tight margins due to increased fuel and labor costs, not to mention the ancillary expenses of maintaining capital expenditures like vehicles, tools and other equipment, is challenging. An unanticipated materials increase puts a contractor already locked in pricing with clients into a difficult situation: Do they “resell” the cost hike to a customer or eat the difference in a loss leader strategy?

Having authored many price increase announcements in my career, I gained some insight that might be helpful for your contractors when explaining why increases are necessary. I found that when a contractor can clearly articulate a valid reason for a price increase, it’s not as bothersome as some believe.

For example, I replaced my home’s heating and air conditioning system several years back. The HVAC company came out, made a great presentation, and explained that equipment was in short supply due to the record freeze issue in Houston that year.

The weather caused a major compressor manufacturing facility to go offline, driving up material costs and restricting supply, which made sense; I appreciated the candor and ended up buying the system anyway.

How to Be Helpful

Here are several approaches suppliers can employ to help earn greater trust with their contractors as they balance branch profitability against their reputation with their customers when implementing price increases. While some contractors will just eat the cost and accept a smaller profit margin, others want to increase their bids effectively to cover those increases.

Either way, the following are best practices for every supplier:

- Be honest. Give your contractors the same courtesy you expect from your manufacturer partners. Be clear and forthright, and give them enough notice to work the increase into future bids without jeopardizing jobs that have already been sold.

-

Be clear. Give contractors talking points they can use with their homeowner customers. Make those points relevant to current economic or other conditions, and in plain speak so they can be articulated clearly.

- For example:Supply chain issues are causing delays in raw material shipping; political strife in Venezuela is causing asphalt suppliers to limit shipments and raise prices to roofing manufacturers; trucking delays; storms in the south are driving unprecedented demand and higher prices. You get the idea.

- Talk to your contractors. Every few months, especially during the slow season, have a roundtable session with your best contractors and ask them how you can help ease this issue and anything else on their minds. Listen to their concerns and work together to come up with great strategies.

A note of caution: Be careful how you talk about increases and how contractors can manage them with homeowners. In a room full of contractors, that kind of discussion may be perceived as “collusion,” otherwise known as price-fixing, which is illegal. Keep money conversations general. Focus on how to address the “why” of the increase more than the amount of the increase.

At the end of the day, it all boils down to clear, consistent, honest communication. It helps build loyalty and trust with your contractors.

Report Abusive Comment