The Raymond Corporation’s headquarters in Green, N.Y., said on Tuesday it was celebrating 100,000 employee-submitted ‘kaizens,’ a program rooted in the Japanese philosophy that translates in English as “continuous improvement” began in 2006.

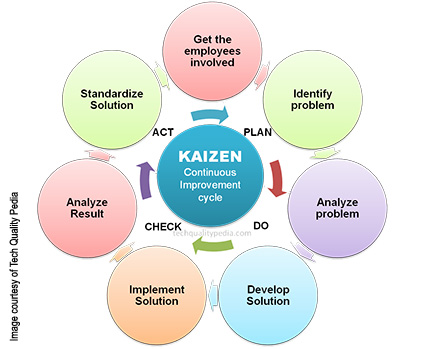

Kaizen is based on the idea that small ongoing changes over time will result in significant improvements. The concept, while unique in the West, is not new. As a Toyota UK blog post from 2021 notes, “Kaizen is a philosophy that helps to ensure maximum quality, the elimination of waste, and improvements in efficiency, both in terms of equipment and work…” measures.

“Demonstrating pure initiative and a collaborative nature, the Greene, N.Y., operational team deserves great recognition for 100,000 kaizens submitted,” said Tony Topencik, vice president of operations, quality and EHS at The Raymond Corporation.

“Raymond encourages its employees at all levels and tenure to submit kaizens they believe will help improve their departmental processes,” Topencik added. “With each kaizen that is selected and acted upon, it further demonstrates to team members that their voices are valued.”

In a Jan. 30 news release, Raymond noted that submitting Kaizens is not mandatory, but the company continues to see employee engagement with this process; Kaizen submissions even withstood the challenging times of COVID-19 and continue to foster connectivity and culture within the organization.

The Greene, N.Y., operation has 28 departments and more than 2,900 employees who submitted at least one Kaizen, Raymond said, adding that more than 80% of Kaizens submitted have been implemented to date.

The Greene, N.Y., operation has 28 departments and more than 2,900 employees who submitted at least one Kaizen, Raymond said, adding that more than 80% of Kaizens submitted have been implemented to date.

The company estimates that 5,427 days were saved by “eliminating waste and improving processes” through Kaizens. In total, across Raymond, which consists of 110 departments spanning three locations, the company has secured 19,883 days saved, with 4,384 employees having submitted at least one kaizen since 2006.

The Raymond Corporation is tracking toward hitting 150,000 kaizens enterprise-wide within the year and sees, on average, 843 kaizens submitted monthly.

“Kaizen is a foundational part of Raymond Lean Management [or RLM], which is built on the proven foundation and principles of the world-renowned Toyota Production System,” Topencik said. “The program teams up with associates across the organization — from the manufacturing floor to office departments, dealerships and more — to coach them on continuous improvement concepts.”

Employees are said to receive well-deserved recognition during a monthly review, where four implemented kaizens are selected. Implemented kaizens shine a light on the employees who submitted their work, with a presentation by Raymond’s president & CEO, VP of operations, director and senior manager for the area, and direct supervisor. The kaizen winner talks about their work and receives both a monetary award and a certificate of recognition.

“At Raymond, we believe in celebrating excellence at every level. Our monthly kaizen reviews recognize our employees' hard work and innovation and exemplify our commitment to continuous improvement. Implemented kaizens are a testament to our collective dedication to excellence, and through these moments of recognition, we illuminate the path to continuous success,” said Topencik.

“Of all the data measured by organizations, moral metrics are of great importance to us,” he added. “This is a critical part of our culture and encourages peer-to-peer positivity. It confirms that together, we are going in the right direction.”

For more information, visit raymondcorp.com/optimization/lean-management.

Report Abusive Comment