In the world of roofing-oriented distribution, we have been using machines to do our heavy lifting from day one. How much business could you do if you simply opened up shop and waited for roofers to stop by and pick up their materials from you? How long would it take to load their trucks if you had to do it by hand?

We are proficient in receiving and shipping goods and well-equipped to take on these tasks with limited human-required labor. Our loaders are primarily equipment operators. We have been using computers to monitor our inventory and accounts for nearly fifty years.

So, why do we still struggle to keep an excellent accounting of our inventories?

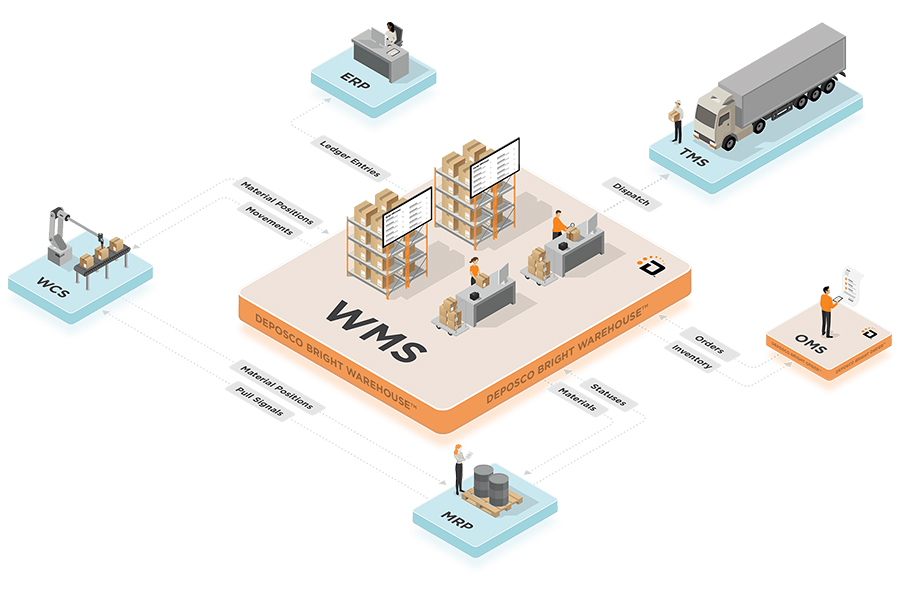

Let’s take a look at computerized warehouse management systems, known in the trenches as WMS. These systems have been around almost as long as the computing systems on which they operate. Most of these systems with which I am familiar (and I do not know them all) provide a framework that can give excellent accounting for inventories in all stages of inventory.

I have observed, however, that WMS, as most roofing supply companies use them, typically do not operate at their designed level of capability; either there is a lack of ‘buy-in’ from leadership, or they are cost-prohibitive to operate.

The “optimal level” means taking the WMS to its ultimate step — mechanization — which requires peripherals like barcode scanners and paperless picking. I thought we would have been all-in by now, but the truly digital warehouse is a rarity in roofing and building products wholesale distribution.

I learned from one early adopter that the biggest challenge to making good on further mechanizing a WMS is how it gets used in its ‘manual’ form. WMS software is constructed to execute tasks by entering a unique formula for every action that goes into it. Falling short of using the WMS according to the system protocols will only frustrate the implementation of a further mechanized system.

For example, your WMS calls for you to carry out certain specific steps for receiving goods into your warehouse. Most deliveries using WMS are anticipated ahead of arriving at the dock by way of a digital document (purchase order, transfer order, or return goods order). The receiving manager needs only match the goods delivered to the incoming paperwork and tell the WMS it has gone through the intake.

From here, a sophisticated WMS will tell the operator where to put the goods, which requires a digitized map of the entire warehouse. Alternatively, the operator may choose where to store the goods and then tell the WMS where they are: This is where receiving ‘issues’ begin. From that deviation, unforeseen snafus, like unscheduled stock-outs and other manners of inventory problems, creep up.

A fully automated WMS can significantly reduce the number of physical steps the operator must take (back and forth between the loading and the computer terminal) as well as the number of potential errors that can occur at each step.

Every interface between the operator, the goods, and the WMS is an opportunity to get it 100% right or start a domino effect — an error that builds, ultimately resulting in a poor customer service outcome. In my opinion, every automated interface that is digital-capable (i.e., barcode reader) will produce a better outcome in the aggregate.

Receiving is just the beginning; accounting for the receipt of goods is where a lot, if not most, problems with inventory accuracy happen. I will let this sit with readers rather than go on about other ‘opportunities’ between delivery and a square of shingles on the roof; you get the picture.

The Upshot

Developers working in concert with distribution professionals have created unique systems to account for inventories and manage warehouse operations. Some operators have dedicated themselves to using these systems to their maximum benefit.

In contrast, others have cherry-picked parts of their WMS just to do the fundamental job of maintaining an accounting of their inventory, accepting “less than excellent” results for their business.

With the labor pool shrinking unabated and the cost of labor rising, it is time to reconsider how you operate your WMS and then take the next step — go all-in.

Is it the right one for your business? Should you consider full mechanization with barcode devices and a paperless receiving and delivery scheme?

Keep an eye on Roofing Supply Pro as we commit to reporting on this and other ways to improve your roofing supply business.

Report Abusive Comment